Back

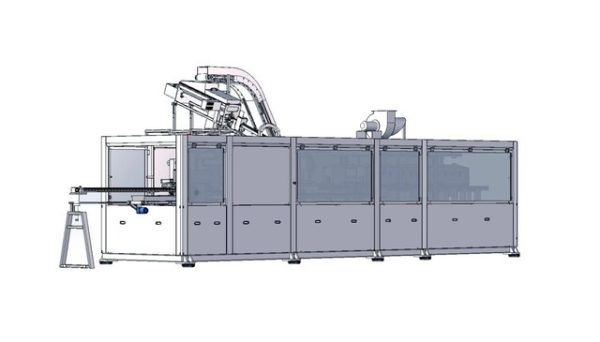

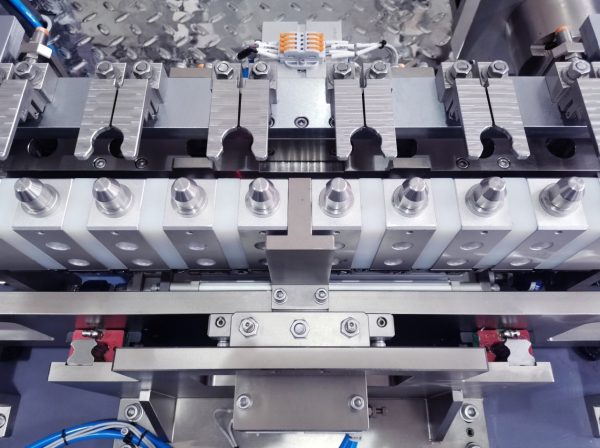

ISBM Blow Molding Machine

It is adopted smart high-accurate auto voltage control system the equipment can accurately control preform temperature and greatly save manpower, raw material and energy.

-

Description

-

Reviews (0)

Reviews

There are no reviews yet.