|

Description |

Unit |

Model:

SIV4 |

|

Number of Blowing cavities |

N° |

4 |

|

Machine output. |

BPH |

4500 BPH (250ml) 4000 BPH (500ml) |

|

Max. Capacity. |

ml |

1000 |

|

Max neck diameter. |

mm |

32 |

|

Max preform height (neck included) |

mm |

300 |

|

Total installed power. |

kW |

136 |

|

8 bar standard service air requirement. |

m3/min |

3 |

|

25 bar standard service air requirement |

m3/min |

4 |

|

20°C cooling water for heater requirement (delta T: 2°C) Heating Box |

m3/min |

4 |

|

10°C cooling water for blow mold requirement (delta T: 2°C). Blow Mold |

m3/min |

6 |

|

Water inlet pressure requirement. |

Bar |

3-4 |

|

Layout (Include preform conveyor). |

mm |

6500x4300x3400 |

|

Net weight |

T |

7 |

|

1)

STANDARD FEATURES: i)

Touch

screen Operator Interface with automatic process setting, maintenance

procedures, troubleshooting guide and diagnostics. ii) Preform conveyor iii) Preform Unscrambler device iv) The hanger automatic welding device v) Synchronized automatic connection device vi) Standard set of maintenance tooling. vii) Wiring diagrams, Operation and maintenance

manuals, spare parts list in English language. |

||

Item | Unit | Quantity | |

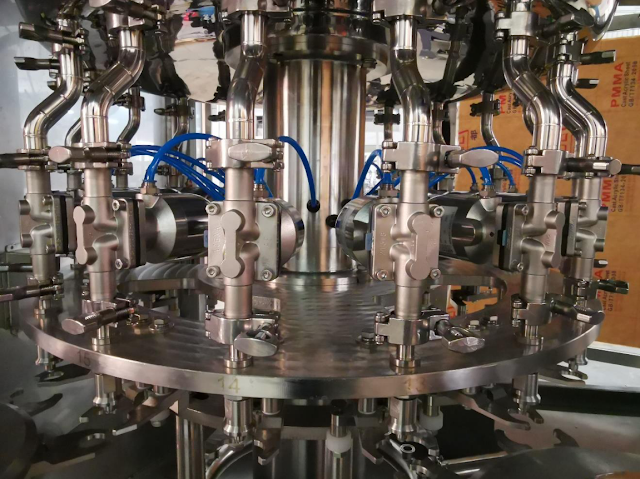

Model: SQHF18/18/24 | |||

Capacity | 500ml | Pcs/h | 4000 |

Formats |

| ml | 250/500 |

Washing unit |

| n | 18 |

Filling unit |

| n | 18 |

Welding unit |

| n | 24 |

Total power |

| kW | 40 |

Air Consumption | 0.5-0.7Mpa | m3/min | 4 |

Size | L*W*H | mm | 4400*1968*2200 |

Gross Weight |

| T | 7 |

Quality Index | Measurement error |

| ≤±1% |

Welding error |

| ≤±0.5mm | |

0 Comments